How Custom-Built Heat Exchangers Solve Industry Challenges

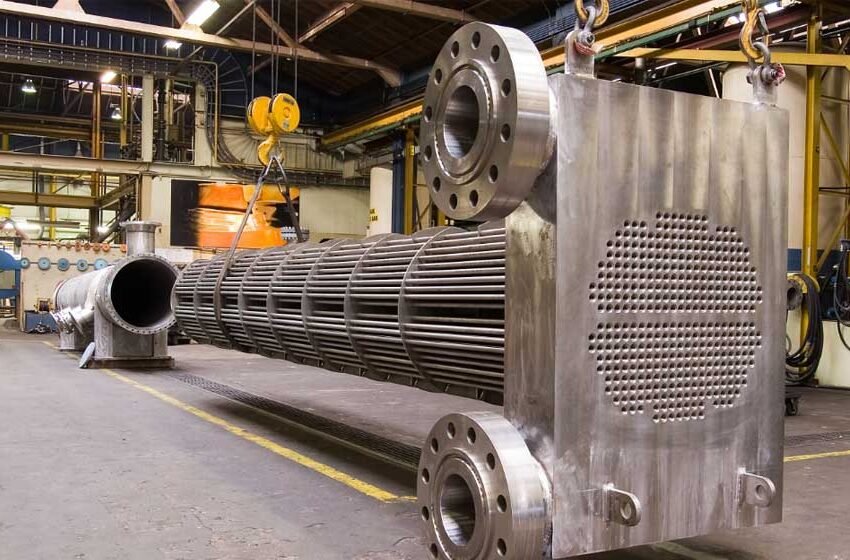

Industries that rely on thermal management—such as manufacturing, power generation, and chemical processing—often face unique operational demands that off-the-shelf equipment cannot always meet. Standard heat exchangers may fall short when it comes to performance under extreme temperatures, pressure conditions, or corrosive environments. Custom-built solutions offer a way to address these specific needs, enhancing both efficiency and longevity of critical systems.

Designing a heat exchanger tailored to a particular application allows for greater precision and adaptability. Variables such as size, material composition, and configuration can be optimized to match operational requirements. A heat exchanger company can collaborate with engineers to refine these designs, ensuring they meet safety standards while also solving long-standing operational challenges. This approach not only reduces downtime but also improves energy use, making it a practical choice for industries aiming for reliable and sustainable solutions.

Addressing Unique Operational Needs

Standardized heat exchangers are insufficient for the diverse operational conditions in industries like chemical processing and pharmaceuticals. These industries require robust alloys, unique flow geometries, and innovative construction methods to withstand harsh environments. Custom-built heat exchangers consider every operational variable, allowing engineers to design models that address potential issues like fouling, excessive vibration, or non-uniform flow distribution. Unlike mass-produced solutions, this tailored approach maximizes uptime, maintains consistent product quality, and ensures compliance with safety requirements.

Enhancing Efficiency Through Advanced Manufacturing

Modern manufacturing techniques have revolutionized heat exchanger design and construction, including laser precision cutting, robotic welding, and advanced surface treatments. 3D printing, a game-changing technology, allows for complex structures that traditional methods cannot replicate, improving fluid dynamics and heat transfer pathways. University of Illinois engineers demonstrated that 3D-printed heat exchangers can deliver up to a 2000% performance improvement, resulting in more compact, less prone to pressure losses, and easier integration into tight spaces. Advanced manufacturing enhances industrial heating and cooling solutions’ performance, reliability, sustainability, and cost-effectiveness.

Improving System Performance and Reducing Costs

Custom-built heat exchangers offer numerous benefits beyond high thermal transfer rates. They can integrate with existing processing lines and automation, reducing inefficiencies and costs. Modular construction allows for easy maintenance, and corrosion-resistant materials reduce premature failure risks—these engineering enhancements lower repair costs and unplanned shutdowns, impacting a company’s bottom line. Optimized thermal systems can significantly reduce energy consumption, especially in energy-intensive sectors like power generation, petrochemicals, or food processing. Companies benefit from enhanced operational uptime and lower ownership costs, making custom heat exchangers a strategic investment.

Ensuring Compliance and Safety

The regulatory landscape for processing equipment is becoming more stringent, especially in sectors like pharmaceuticals, food, and clean energy. Custom heat exchangers meet standards from ASME, API, GMP, and FDA, often with special finishes for sanitation, high-quality welds, seals, or double-walled designs for leak detection. Incorporating safety and compliance helps companies protect public safety, the environment, their reputation, and finances, avoiding fines, recalls, and legal issues.