How Sustainable Businesses Use Board-Level Repairs to Cut E-Waste

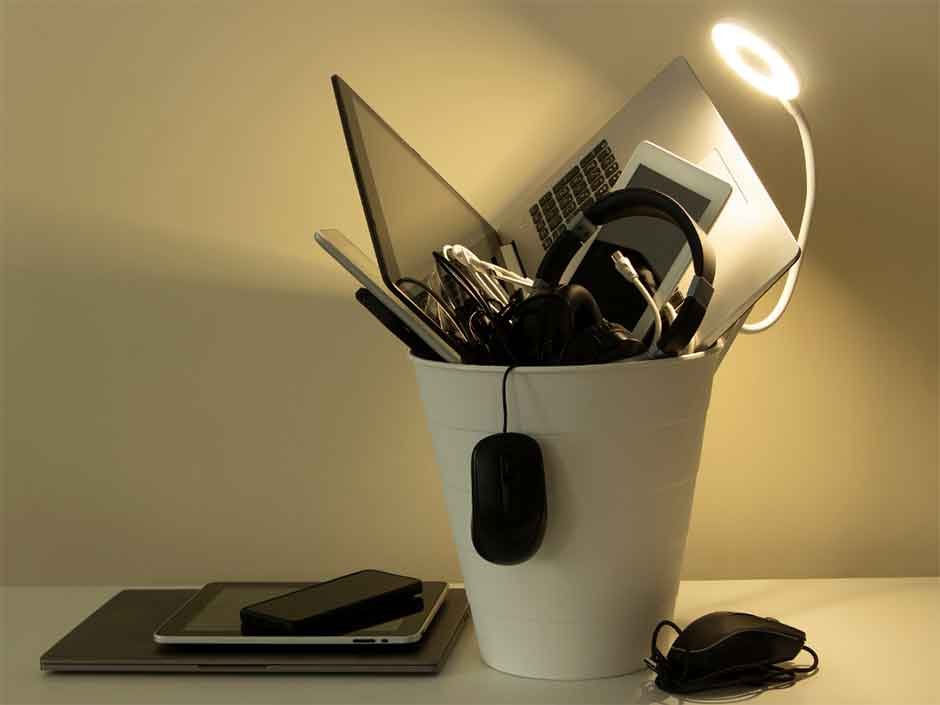

Sustainability has become an essential part of how modern businesses operate. Companies everywhere are looking for practical ways to shrink their environmental impact, and electronic waste (e-waste) has become one of the most pressing issues they face. Each year, millions of tons of electronic devices are discarded globally, and a significant portion of this waste comes from businesses upgrading or disposing of equipment. However, forward-thinking companies are turning to board-level repairs as a practical and cost-effective solution.

This article explores how sustainable businesses leverage board-level repairs to reduce e-waste, extend the life cycle of electronics, and lower costs. We’ll look at why board-level repairs matter, the role of skilled technicians, practical implementation strategies, and the measurable impact on sustainability goals.

Understanding Board-Level Repairs and Their Importance

Board-level repairs involve working directly on the circuit boards of devices rather than simply replacing entire components or units. This process often includes identifying and replacing defective chips, connectors, capacitors, or resistors to restore functionality. In many cases, what might be considered a “dead” device can be revived through these precision repairs.

For example, instead of discarding an entire laptop or network switch due to a single failed power IC or burned-out capacitor, businesses can have the faulty component repaired or replaced at the board level. This approach reduces the number of devices sent to recycling facilities or landfills and saves significant money.

The demand for skilled repair technicians has grown in parallel with this shift. Many businesses now outsource these repairs to specialist providers offering micro soldering repair services to deal with intricate board-level faults. This expertise allows companies to keep equipment in service longer, lowering their overall carbon footprint and keeping hazardous materials out of the waste stream.

Practical Steps for Businesses to Adopt Board-Level Repairs

Adopting board-level repairs within a business’s sustainability plan requires a systematic approach. Below are actionable steps that organizations can follow to integrate this practice into their operations:

1. Conduct an Equipment Audit

The first step is to understand what electronic devices a business currently owns and how often they are replaced or discarded. This includes computers, monitors, servers, networking gear, POS systems, and even smaller devices like tablets and handheld scanners. By mapping out this inventory, businesses can identify high-failure items and evaluate the potential for repairs instead of replacements.

2. Partner with Certified Repair Providers

Not all repair services are equal. Companies should work with certified technicians who have experience with complex electronic repairs. Industry certifications, such as IPC (Association Connecting Electronics Industries) standards, are a good indicator of quality work. Partnering with a provider that documents each repair can also help businesses track savings and sustainability metrics.

3. Train In-House IT Teams

While outsourcing is often necessary for highly complex repairs, in-house IT teams can be trained to identify which issues are candidates for board-level repair. Early diagnosis reduces downtime and ensures equipment is repaired before small faults turn into catastrophic failures.

4. Build a Repair and Reuse Policy

To formalize the process, businesses should create a repair and reuse policy. This document can outline when devices should be sent for repair, criteria for replacement, and the preferred vendors. Policies also help educate employees about the company’s commitment to sustainability, creating a culture that values repair over disposal.

Environmental and Financial Benefits

The impact of board-level repairs extends far beyond cost savings. According to the Global E-Waste Monitor 2024, the world generated over 60 million metric tons of e-waste in a single year. Much of this waste is toxic, containing lead, mercury, and other hazardous materials that can pollute soil and water when not properly disposed of.

By extending the lifespan of devices through repair, businesses contribute to:

- Waste Reduction:Fewer devices end up in landfills, reducing pollution and conserving landfill space.

- Resource Conservation:Repairing electronics reduces the demand for raw materials such as copper, gold, and rare earth elements that are mined at significant environmental cost.

- Lower Carbon Emissions:Manufacturing new electronics requires energy-intensive processes. Repairing equipment instead of replacing it avoids the emissions associated with new production and shipping.

On the financial side, the savings can be substantial. Board-level repairs typically cost a fraction of full replacements. For example, a failed motherboard in a laptop might be repaired for 30–40% of the cost of a new device. This allows businesses to redirect savings toward other sustainability initiatives, employee development, or innovation projects.

Measuring and Reporting Results

One of the keys to long-term success in any sustainability initiative is the ability to measure and report results. Businesses that implement board-level repairs should track metrics such as:

- Number of Devices Repaired vs. Replaced

- Estimated E-Waste Avoided (in kg or metric tons)

- Cost Savings Achieved

- Average Life Extension of Equipment (in months or years)

This data can be included in annual sustainability reports, helping companies demonstrate their commitment to environmental responsibility to stakeholders, investors, and customers. Publicizing these results also strengthens brand reputation, which can lead to increased customer loyalty.

Challenges and Considerations

While board-level repairs offer many advantages, businesses must also be aware of potential challenges. Repairing complex electronics requires highly skilled technicians, and not all devices are repairable. Some manufacturers use proprietary components or designs that make repairs difficult. In these cases, businesses may need to work with vendors who specialize in reverse engineering or push for right-to-repair legislation that promotes accessibility to parts and schematics.

Data security is another consideration. Before sending devices for repair, businesses must ensure that sensitive data is backed up or securely wiped. Partnering with trusted providers who follow strict data handling protocols is essential.

Board-level repairs are a powerful tool for businesses seeking to reduce e-waste, cut costs, and enhance their sustainability efforts. By working with skilled technicians, training IT teams, and implementing formal policies, companies can extend the life of their electronics while contributing to global efforts to reduce pollution and conserve resources.

In a world where sustainability is becoming a competitive differentiator, businesses that invest in repair-first strategies are setting themselves up for long-term success.